My Projects

Below the slideshow you can find details on many of the professional, educational, and personal projects I have taken on. Examples of some of the projects are: The Screw Propelled Front Loader I designed for Los Alamos National Laboratory and the Department of Energy for use at the Hanford Site; Texas A&M’s Electronic Garage Signs; The five trucks, five motorcycles and a 1982 Datsun 280ZX I bought/sold through college.

.

.

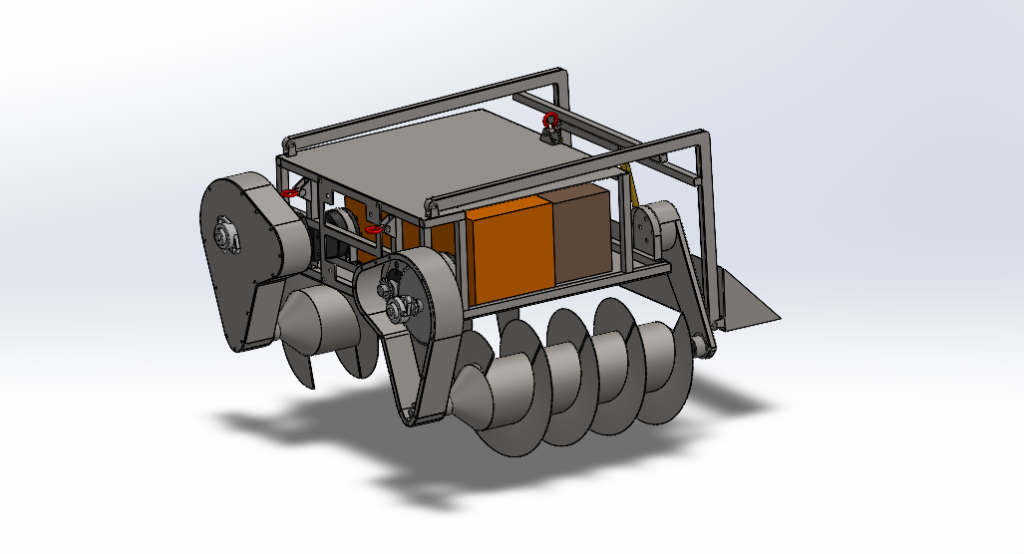

Screw Propelled Front Loader for Los Alamos National Laboratory and The Department of Energy

My undergraduate engineering capstone project is designing, manufacturing, and testing of a screw-propelled front loader for LANL and the DOE. In addition, I submitted a prospective research paper to the American Society of Construction Engineering conference hosted by LSU in New Orleans. This paper was accepted, and I will be presenting my findings at the conference. I was tasked with designing a remote-control solution for navigating and excavating material in nuclear waste tanks at the Hanford Site in Washington. My novel approach was to utilize screw propulsion to overcome traction limitations posed by this problem as the medium being navigated is a heterogenous mixture of sludge and salt-cake waste. While fulfilling certain design requirements and constraints, I designed the robot’s structure, electrical system, and hydraulic systems. The robot utilizes a RC system that controls an industrial scale hydraulics system capable of moving at more than 60 feet per minute and lifting over 150 pounds.

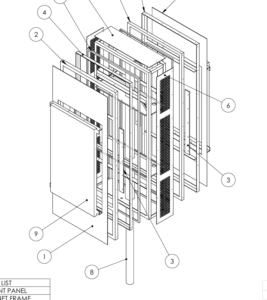

Texas A&M Electronic Garage Signs

During my co-op experience with Rik-Mar Fabricators, I was tasked with updating and creating new drawings for Texas A&M’s electronic garage signs used outside of the garage parking. These signs housed a Samsung screen that displayed garage capacity information and other messages for patrons entering and leaving the garage. These signs were then fabricated at the shop, where I assisted in manufacturing and helped communicate the design through my manufacturing drawings.

Buying and Selling ("Flipping") of Multiple Vehicles

Starting in high school, I developed a passion for automotive engineering. My first project I was a 1982 Datsun 280ZX with a drivetrain swap from a 1996 Chevrolet C1500 as a part of my senior year capstone project with South Texas Auto. During college, I bought and sold five Ford trucks; two 1997 F-250s; a 1994 F-150; a 1981 F100; and a 1978 Bronco. I also bought and sold five motorcycles; a 1992 Kawasaki Vulcan 750; a 1988 Harley Davidson Sportster 883; a 2000 Harley Davidson Wide Glide; a 1982 Suzuki GS750; and a 2004 Harley Davidson Sportster 1200. I did major work on several of these projects. I still have the two 97′ F-250s and the 78′ Bronco. One of the 97′ F-250s is my daily driver. I replaced the fuel system, one ton axle swapped, rebuilt the suspension, rebuilt the doors, rebuilt the pedal box, and many more modifications.

Pictures to come

Various Manufacturing Projects

During my time at Texas A&M I gained experience in several different manufacturing methods. Some experiences include 3D extrusion printing, laser engraving, milling, lathe operation, CNC demonstration, welding, metal forming, metal casting, injection molding, vacuum molding, composite wet-layup, and ceramic slip casting.

Various Software Projects

Through my degree program at Texas A&M I worked on several major software projects such as using robotic arm programming and integration with programmable logic controllers, database programming with visual basic, producing NC Code for CAM systems, and 3D scanning.

Pictures to come